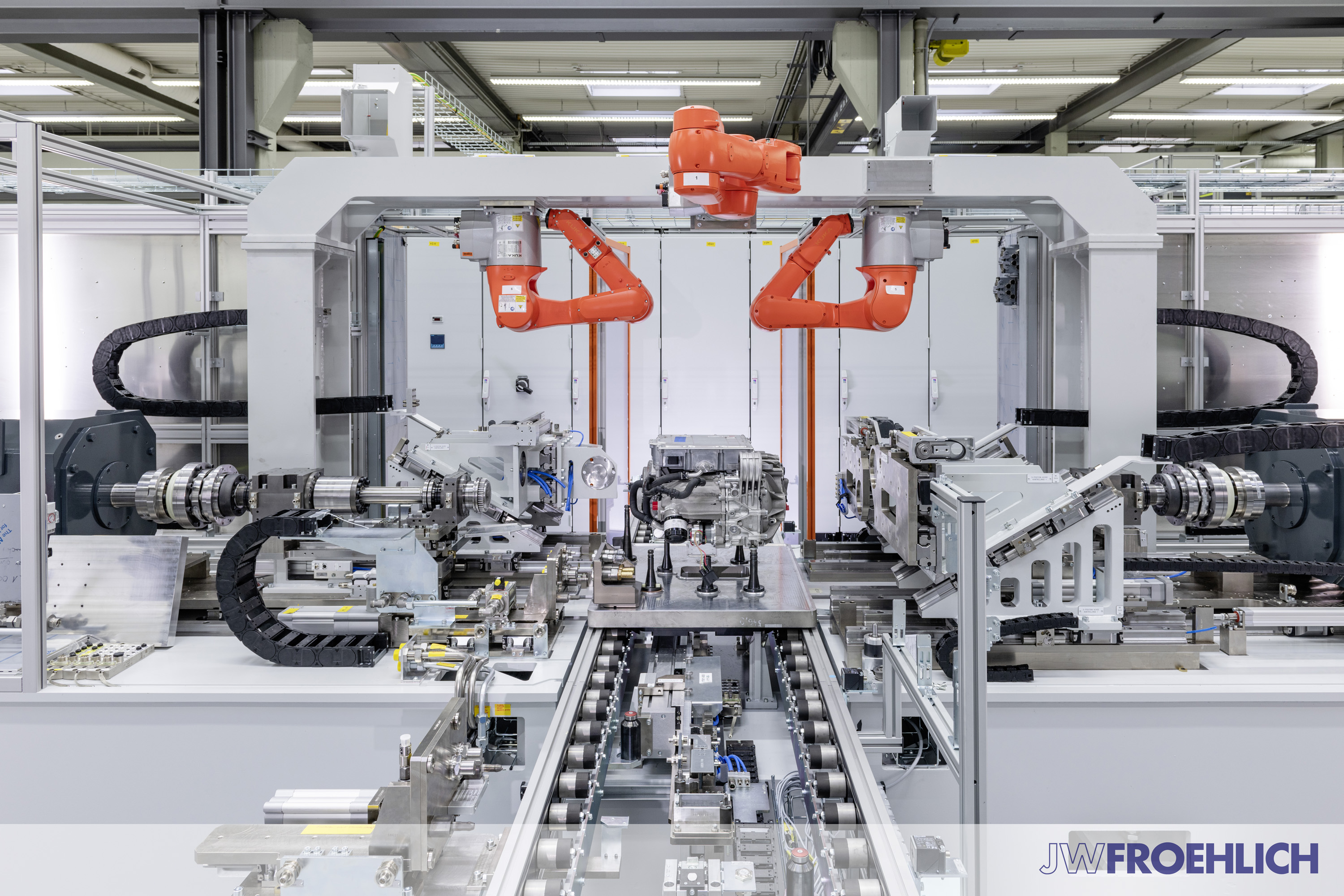

End-of-Line (EOL) Functional Tester

JWF X TeSys Partnership

The requirements of test stand performance for electric drive units (EDU) and their components can vary greatly and strongly depend on the intended application: Development test stands, for example, are highly flexible, but are usually set up manually. Q test stands are used for establishing test parameters for the pre-series and provide a link between development and production. Finally, end-of-line (EOL) test stands have to be particularly efficient, which is why they are often mostly automated. Advice by JW Froehlich on the application-oriented development can help to achieve better cost efficiency, for example by reducing cycle times and limiting the tests to the necessary range of performance and measurements.

JWF + TeSys - E-Mobility & Automotive - Electric Drive Unit - EOL Functional Tester (EDU, PPE)