Emission Test Bench

Chassis dynamometer having world class control algorithms coupled with innovative mechanical designs and integration technology has been completely developed over the acquisition period by TeSys for Hofmann TeSys GmbH and Froude Hofmann chassis dynamometer product IP (Intellectual Property) from 2016 up to 2018.

Now, TeSys can present a strong platform for the compete range of chassis dynamometer products contributable to Research and Development purpose with configurable versions for Battery Efficiency (PHEV, HEV, BEV), Emission, Performance/Endurance, Climatic, NVH testing facility and other bespoke applications to suit Military, Heavy/Medium/Light Duty vehicles as well as Motorcycle / AGV / ATV / 2-wheelers. Our chassis dynamometer has multiple solutions from a simple 1 wheel drive motorcycle to a fully independent 16x16 special commercial vehicle system applicable to conventional and e-drive vehicles.

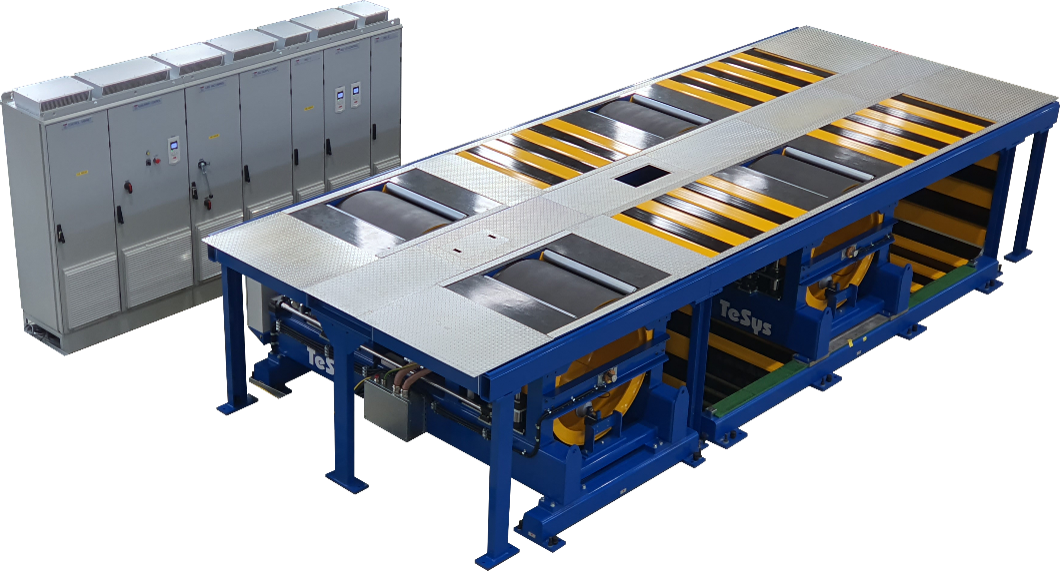

TESYS - Dynamometer - Chassis Dynamometer (LDV) - Emission Test Bench