Battery Test Bench

JWF Reference (Agency)

Permanent leak tightness (IP67) is a key prerequisite of batteries used in e-mobility. Testing must produce safe and reliable results to avoid short circuits due to splashing. Helium leak testing has a major advantage over air leak testing: It is able to detect even very small leaks (ca. 2.5 cm³ at 50 mbar). There is very little helium in the ambient air, enabling reliable test results even when only slightly increased concentrations of the gas can be detected.

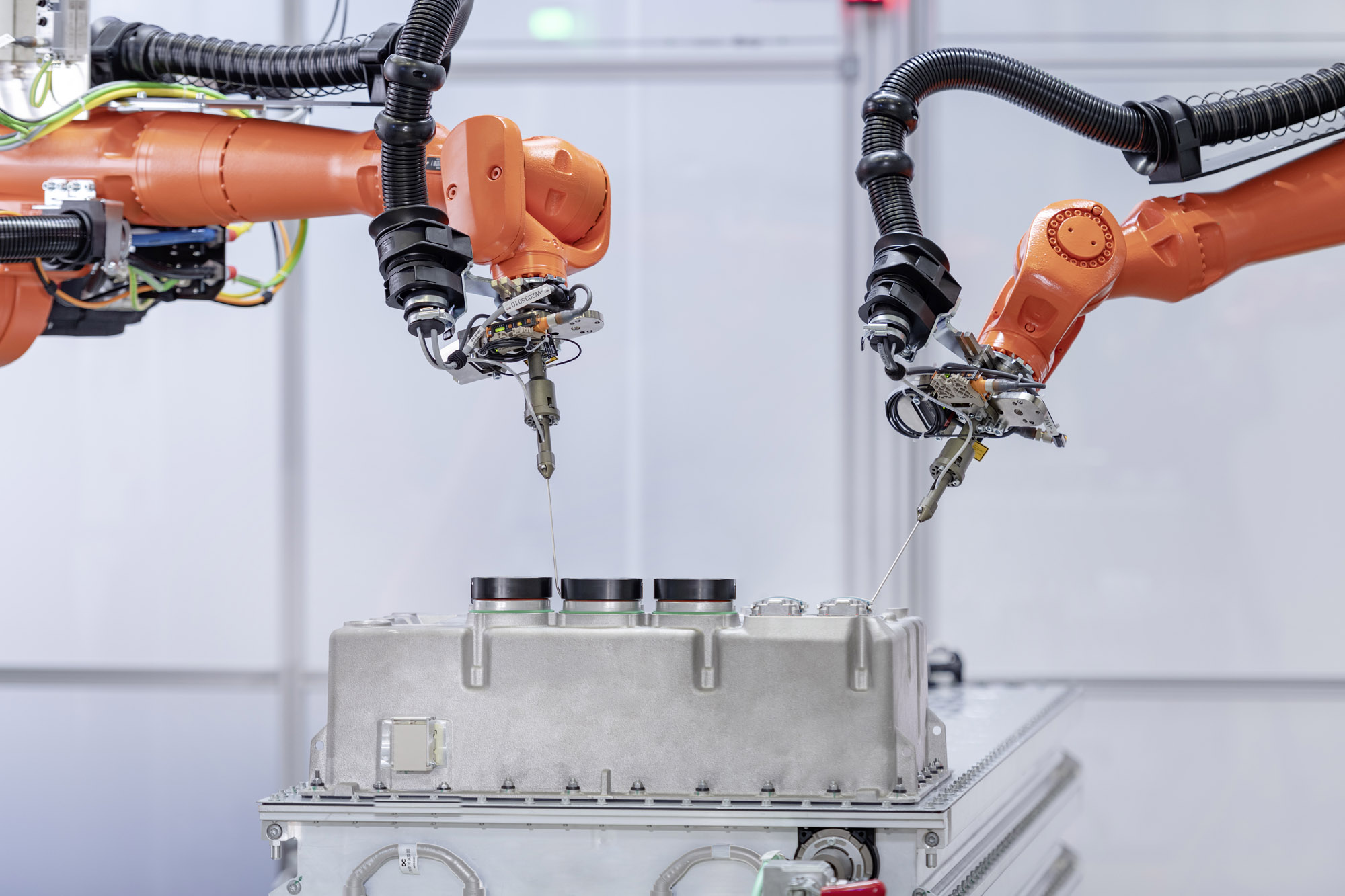

The helium sniffing test uses a sniffer probe to scan all possible leakage points of a test part filled with helium, enabling it to particularly reliably and accurately detect and later repair possible faults. The concentration of the helium/gas mixture can vary depending on the task at hand, making it possible to use it cost-efficiently. JW Froehlich has decades of experience in this field.

A German OEM required test stands which are able to safely test large quantities of components in very little time to start serial production of truck batteries. Their requirement was maximum product and process safety at optimum cost efficiency. A solution for tailor-made and automated test stands for two different locations was developed in close collaboration with the client, and delivered within eight months. Based on these developments, another 20 helium leak test stands were ordered at a later date. Further lines will be equipped by the end of 2024, bringing the total number of helium leak test stands to 30.

JWF + TeSys - E-Drive Leak & Functional Tester - JWF Reference - Battery Test Bench